Reloading is serious business and one should not forget that.

The reloader’s biggest fear is generating overpressure in the chamber when firing a cartridge. Overpressure can cause the gun to break (blow up) with a variety of consequences. Personally, I’m on the cautious side meaning that I don’t “hunt” for +P loads and I work up loads from minimum load data and my reloading process is tuned as much as possible for safety. Still, no-one is free from mistakes, one can only attempt to avoid them. Actually currently I also simulate my loads and check the effect of variations on powder charge and seating depth. I’m keeping pressure 15% off maximum SAAMI pressure.

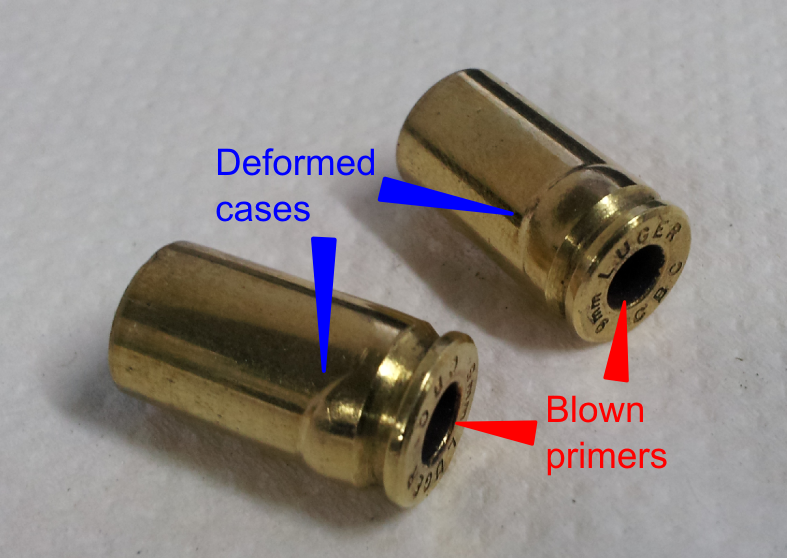

But risks sometimes come from the outside… At some point in time I got some 9mm reloads from an experienced reloader. The picture shows how the cases came out of my Browning Hi-Power after firing. Clearly these were too hot for the gun and a possible safety hazard, luckily I noticed early and only fired a few rounds.

While shooting, I didn’t feel any unusual recoil, but the gun jammed. It jammed because of the blown out primers which hampered the slide going back to battery (loading a new round into the chamber). Inspection of the spent cases also shows a serious bulge at the base of the case as can be seen on the picture. This bulge is caused by the particular design of the Browning Hi-Power. In a HP, a chambered round is unsupported at the bottom as you can see on the figure below (this is different from e.g. a 1911 chamber). Obviously, overpressure causes the case to be pressed against the chamber, at the bottom the brass however deforms as there is no chamber holding it back. Who knows, maybe this has actually prevented the gun from exploding…